Epoxy Decorative Floor Chip Flakes Coating

Epoxy floor flake chips system creates a vibrant, seamless, resilient surface from plain gray concrete. Although the system is simple both

in composition and installation, it yields an exceptionally durable and long lasting floor. This epoxy flake floor system is composed of a binder,

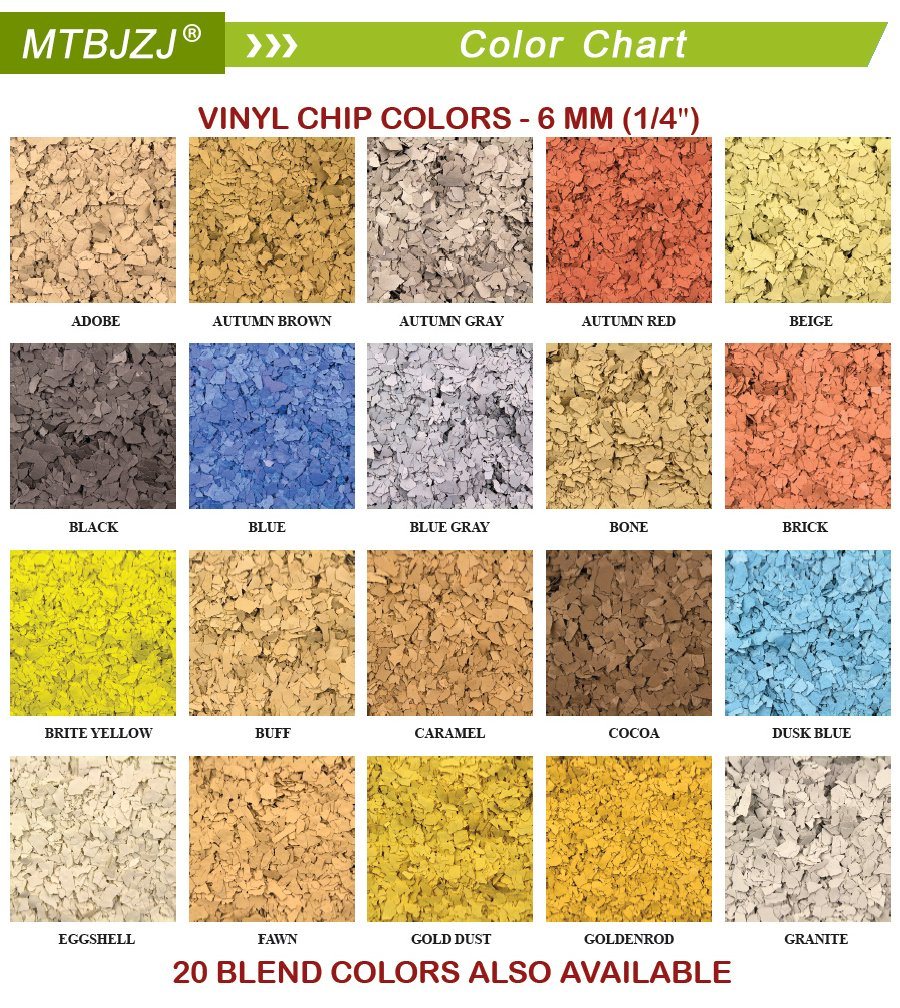

one of the MTB Epoxies and MTB Flakes, randomly shaped polymer chips, available in 20 main color options. The polymer chips provide not

only the pleasing palette of color but also add a measure of slip resistance to the surface. MTB Epoxy provides the structure and strength of

the system. Due to these properties, the MTB Flakes epoxy flake floor system is used for garage floors, commercial kitchens, locker rooms,

sports venues, automotive showrooms, veterinarian clinics, laundromats, or anywhere that an exceedingly resilient floor is required.

in composition and installation, it yields an exceptionally durable and long lasting floor. This epoxy flake floor system is composed of a binder,

one of the MTB Epoxies and MTB Flakes, randomly shaped polymer chips, available in 20 main color options. The polymer chips provide not

only the pleasing palette of color but also add a measure of slip resistance to the surface. MTB Epoxy provides the structure and strength of

the system. Due to these properties, the MTB Flakes epoxy flake floor system is used for garage floors, commercial kitchens, locker rooms,

sports venues, automotive showrooms, veterinarian clinics, laundromats, or anywhere that an exceedingly resilient floor is required.

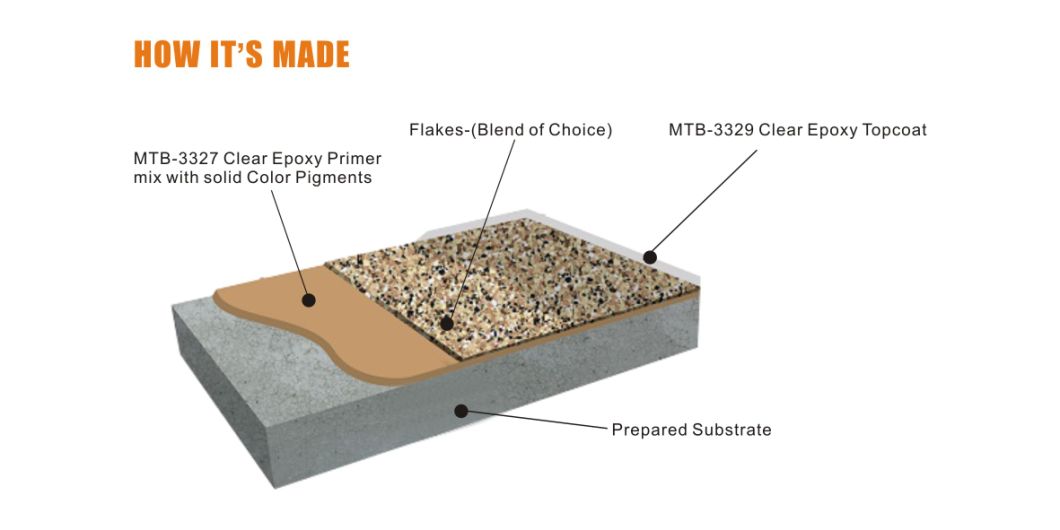

For the whole process of Epoxy floor flake chips system ,you will need

MTB-3327 Epoxy Primer--Coating on the cement floor itself and coating permeability can strengthen the adhesion.In common it is clear ,

100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1,you can mix with the liquid colors or metallic powder

pigments according to your requirements .To fill on the cracks and holes of the concrete and cement floor to make the surface smoothly and

bond tight to aviod peel off easily.

MTB-3328 Epoxy Middle layer coating --It greatly enhance coating floor wear-resisting degree, density, improve the service life and make

the perfect transition between the bottom and the surface layer. In common it is clear ,100% solid content ,two components of epoxy resin and

hardener ,with the mix ratio of 2:1,you can mix with the color flakes or chips according to your requirements .To make your floor colorful as what

you need .

MTB-3329 Epoxy Self-level Surface Coating Layer or Top layer Coating

100% solid content ,two components of epoxy resin and hardener ,with the mix ratio of 2:1,you can mix with the liquid colors or metallic powder

pigments according to your requirements .To fill on the cracks and holes of the concrete and cement floor to make the surface smoothly and

bond tight to aviod peel off easily.

MTB-3328 Epoxy Middle layer coating --It greatly enhance coating floor wear-resisting degree, density, improve the service life and make

the perfect transition between the bottom and the surface layer. In common it is clear ,100% solid content ,two components of epoxy resin and

hardener ,with the mix ratio of 2:1,you can mix with the color flakes or chips according to your requirements .To make your floor colorful as what

you need .

MTB-3329 Epoxy Self-level Surface Coating Layer or Top layer Coating

Can make the whole coating project to determine the role of color, luster bright, smooth and lively, the abrasion resistance, acid and alkali

resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,

with the mix ratio of 2:1 .To make the top floor finished much more glossy and brighter and shines brightly like glass .

resistance, oil resistance, resistance to water, dust, etc. In common it is clear ,100% solid content ,two components of epoxy resin and hardener ,

with the mix ratio of 2:1 .To make the top floor finished much more glossy and brighter and shines brightly like glass .

• Epoxy flake can be installed on concrete floors in one day

• Low VOC green products

• Non-yellowing

• Extremely fast drying

• Can be retarded for more potlife

• Penetrates deep into porous concrete

• Abrasion resistant flooring system

• Resistant to most chemicals

• High build finish

• Hot tire resistant

• Low VOC green products

• Non-yellowing

• Extremely fast drying

• Can be retarded for more potlife

• Penetrates deep into porous concrete

• Abrasion resistant flooring system

• Resistant to most chemicals

• High build finish

• Hot tire resistant

Epoxy Decorative Floor Chip Flakes Coating

Why Epoxy floor flake chips system?

The benefits of epoxy coatings are numerous and varied, making epoxy flooring a preferred option for many businesses.

Here are a few of the reasons our Epoxy Floors will provide your facility maximum benefit!

Affordable

Epoxy coatings offer inexpensive and durable protection for concrete floors, lasting for many years and reducing maintenance

costs over time. Businesses with epoxy coatings often spend less money on flooring over time.

Chemical/Spill Resistant

Epoxy floorings can be formulated to deliver chemical resistance to specific types of chemicals, for businesses requiring this

type of chemical resistance for the safety of their workers.

Safe

With anti-skid, impact resistant and fire resistant options available, epoxy flooring is safe for a variety of industries. This can

improve productivity while reducing incidents and near misses at the work site.

Color Coated

Designate specific work zones within a single building using different color flakes of epoxy flooring for this purpose, indicating

which areas are used for storage, vehicle parking, foot traffic and more.

Durable

Epoxy coating is highly resistant to damage from long-term use, setting up your flooring and work environment for long-term

success.

Attractive

With different colors and patterning flecks available, epoxy coating is an asset in show rooms and stores where product display

is critical to the success of the business.

• High Quality • Non-Porous • Stain-Resistant • Easy to maintain

• Strong & Flexible • UV Resistant • Non-Toxic • Slip-Resistant

Here are a few of the reasons our Epoxy Floors will provide your facility maximum benefit!

Affordable

Epoxy coatings offer inexpensive and durable protection for concrete floors, lasting for many years and reducing maintenance

costs over time. Businesses with epoxy coatings often spend less money on flooring over time.

Chemical/Spill Resistant

Epoxy floorings can be formulated to deliver chemical resistance to specific types of chemicals, for businesses requiring this

type of chemical resistance for the safety of their workers.

Safe

With anti-skid, impact resistant and fire resistant options available, epoxy flooring is safe for a variety of industries. This can

improve productivity while reducing incidents and near misses at the work site.

Color Coated

Designate specific work zones within a single building using different color flakes of epoxy flooring for this purpose, indicating

which areas are used for storage, vehicle parking, foot traffic and more.

Durable

Epoxy coating is highly resistant to damage from long-term use, setting up your flooring and work environment for long-term

success.

Attractive

With different colors and patterning flecks available, epoxy coating is an asset in show rooms and stores where product display

is critical to the success of the business.

• High Quality • Non-Porous • Stain-Resistant • Easy to maintain

• Strong & Flexible • UV Resistant • Non-Toxic • Slip-Resistant

Epoxy Decorative Floor Chip Flakes Coating

Surfaces and locations that can be improved using MTB Epoxy Floor Flake Chips

• Pool Decks and Patios

• Retail Flooring

• Concrete Garage Floors

• Commercial Flooring Applications

• Workshop Areas

• garage floor paint with flakes

• Three-Dimensional Designs

• Epoxy Coating Enhancers

• Multi-Colored Flooring

• Showroom Floors

• Concrete Floors

• Garage Floor Epoxy Coating

•Warehouse• Retail Flooring

• Concrete Garage Floors

• Commercial Flooring Applications

• Workshop Areas

• garage floor paint with flakes

• Three-Dimensional Designs

• Epoxy Coating Enhancers

• Multi-Colored Flooring

• Showroom Floors

• Concrete Floors

• Garage Floor Epoxy Coating

Epoxy Decorative Floor Chip Flakes Coating

Item | Qty | Coverage Data |

MTB-3327 Epoxy Primer | 15kgs Kit, A:10kgs,B:5kgs | 100 Square Meter |

MTB-3328 Epoxy Middle Coat | 15kgs Kit, A:10kgs,B:5kgs | 20 Square Meter |

MTB-3329 Epoxy Top Coat | 15kgs Kit, A:10kgs,B:5kgs | 100 Square Meter |

| Epoxy Flake Chips | 25kgs(50LB) | 100 Square Meter |

For more colors,please send us inquiry.

Epoxy Decorative Floor Chip Flakes Coating