Products Description

Basic Draw

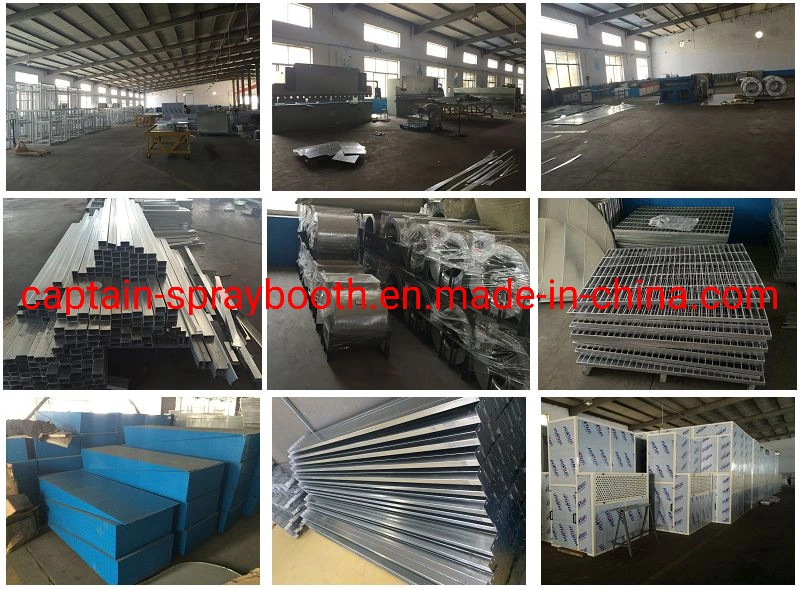

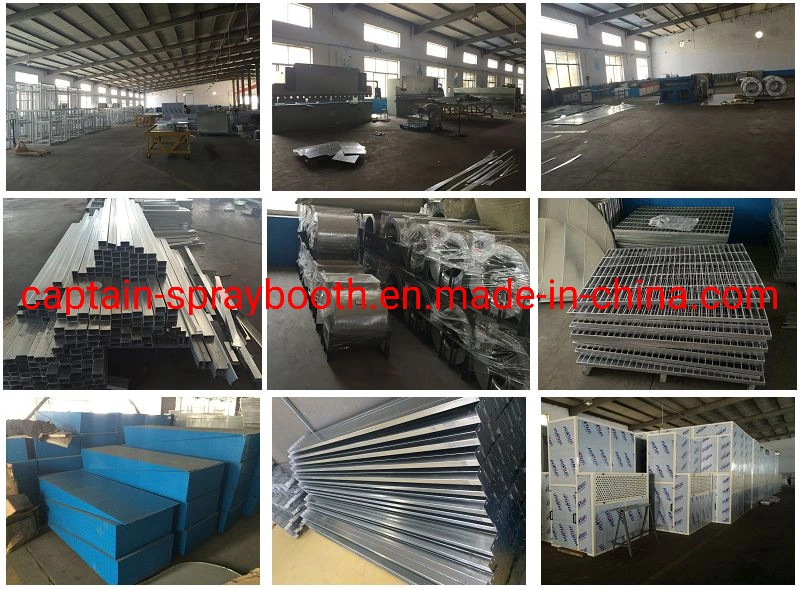

Production

Package and Delivery

Installation

High quality parts

Installed Models

our workshop

factory view

This automatic paint spraying/baking booth is used for air purification during auto paint coating operation and drying operation after painting spray. Paint spraying and drying are performed in the same booth. This paint spraying/baking booth is typical of paint spraying and baking functions, provided with automatic thermostat paint spraying, ventilation, air purification, paint mist treatment, and winter hot-air supply functions during paint spraying, and automatic heating, thermostat timing, and timed shutdown function during paint baking. The equipment is reliable in running, simple for operation, and easy for maintenance.

Equipment Constituents

The equipment of this paint spraying/baking booth is composed of booth structure system, illumination System, air supply system, circulation system, air purification system, paint mist treatment system, pressure control devices, and electrical control system, etc.

Spraying Booth Benefits

1. The device through the action of the wind, water, gas mixture enhanced through the diversion gate, retaining plate, collecting tank, etc., to achieve water and gas separation, thereby overcoming the paint Fog clogging pumps and water systems, causing water system is not working properly shortcomings. As a result of the system without pump water saving devices, saving investment and reducing the footprint.

2. The device is in use, the mist through the water curtain, curtain and roll mixing water and gas passage, multiple classification purification efficiency improves the purification process.

3. Due to the mist and water collecting channel disposed between the diversion gate, both in the collection tank with pressure chamber between the retaining plate also has a diversion gate, to prevent the passage of water vapor mist directly from the collection tank and equalizing chamber is discharged, the purification efficiency improves.

4. Due to the water vapor mixing chamber provided with at least a pan of water board, so that water vapor mist air mixing chamber contains sufficient soluble in water, improve the purification efficiency.

5. Because of the water by adding a mist cleaning agents, paint mist undermine adhesion, cohesion so loose paint mist settling on the bottom for easy cleaning.

6. As in the collection tank with access doors for easy maintenance workers.

Captain Spray Booth(Qingdao Hua Yushun Commercial Co., Ltd)

Is a professional leading factory in China, who is specializing in manufacture kinds of paint spray room system. And also offering full garage equipments, such as

Car care equipment.

Car spray&baking room system

Bus spray&baking room system

Furnitue spray&baking room system

Industrial painting&baking room system

High temperature baking room system

Customized spray&bake booth and Offer car spray baking booth accossories

Services We Supply

Customized service

More Than 90% Of Our Spraying Booth Is Customized.

1. We can design the machines according your requirements. At the same time, our engineers will give you our professional suggestions.

2. We can give you free technical support and consultation such as design your factory, make the factory layout drawing and so on.

After-sales service

1. Our fast and professional after service engineer team can go to your factory and install the machine, give you the operating guidance, and train your employees until they can operate the machine well.

2. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

3. We provide 2 years warranty.

Captain Advantages

*The same price higher quality, the same quality lower price! ! !

*2 years quality warranty! ! !

*Fast and stable supply capability! ! !

*Personalized design to meet customer various needs! ! !

Competitive Price and High Quality Spraying Booth with Perfect Service Is From Here.

Outside Dimension (mm) | 7050 * 5400 * 3250(L*W*H) | Inside Dimension(mm) | 6900 * 3900 * 2600(L*W*H) | |

Front Door(mm) | 2800*2500(W*H) | Service door (mm) | 1800*650(W*H) | |

Total Power | 15KW | |||

Cabin system | Wall panel | 75mm EPS panel, double face steel sheet thickness: 0.5mm | ||

Ceiling panel | Galvanized steel sheet. | |||

Basement | 300mm depth, patented circumferential diamond plate design, middle with grids. | |||

Ramp | two 2000*900mm ramps | |||

Air Make-up System | Air Inlet fan system | 2 * 4 kw double-intake belt centrifugal fan, air capacity for each fan: 14500m3/h. | ||

Exhausted fan system | 1 * 5.5 kw double-intake belt centrifugal fan, air capacity 18000m3/h. | |||

Air Flowing speed | 0.45 m/s in empty booth, 0.35 m/s when painting. | |||

Exhausted ducting | 3 meters air duct, one flop damper, one weather hood, one anti-bird mesh | |||

Water based paint drying system | 20 pieces of air nozzles,10 pieces of nozzles on each corner for drying the Water Based Paint, 2×0.35KW air fans. | |||

Purification System | Pre-filter | G3 grade, Air Inlet filter | ||

Ceiling filter | EU5 / F5 | |||

Floor filter | Green fiber glass filter / G3 grade | |||

Exhausted fan Filters | Fiber glass filter. | |||

Heating System | Heat Exchanger | SUS304 material, argon arc welding. | ||

Heating burner: | Riello G20 diesel oil burner(gas burner for option) | |||

Heating productivity | 200000Kcal/h | |||

Chimney ducting | 2 meters stainless ducting and one chimney elbow | |||

Max heating temperature Heating time | 80 degree centigrade 4-6min(20-60 degree centigrade) | |||

fuel consumption | 5-6L /vehicle | |||

Lighting System | Ceiling lights | 8 Units, each 4 x 36W lamps, Total 1152 W | ||

Side lights | 8 Units, each 4 x 20W lamps, Total 800 W | |||

Illumination | 1200LUX | |||

Controlling system | Switched control panel | Spraying & baking switch, lighting switch, emergency stop, breakdown alarm, failure alarm | ||

Basic Draw

Production

Package and Delivery

Installation

High quality parts

Installed Models

our workshop

factory view

This automatic paint spraying/baking booth is used for air purification during auto paint coating operation and drying operation after painting spray. Paint spraying and drying are performed in the same booth. This paint spraying/baking booth is typical of paint spraying and baking functions, provided with automatic thermostat paint spraying, ventilation, air purification, paint mist treatment, and winter hot-air supply functions during paint spraying, and automatic heating, thermostat timing, and timed shutdown function during paint baking. The equipment is reliable in running, simple for operation, and easy for maintenance.

Equipment Constituents

The equipment of this paint spraying/baking booth is composed of booth structure system, illumination System, air supply system, circulation system, air purification system, paint mist treatment system, pressure control devices, and electrical control system, etc.

Spraying Booth Benefits

1. The device through the action of the wind, water, gas mixture enhanced through the diversion gate, retaining plate, collecting tank, etc., to achieve water and gas separation, thereby overcoming the paint Fog clogging pumps and water systems, causing water system is not working properly shortcomings. As a result of the system without pump water saving devices, saving investment and reducing the footprint.

2. The device is in use, the mist through the water curtain, curtain and roll mixing water and gas passage, multiple classification purification efficiency improves the purification process.

3. Due to the mist and water collecting channel disposed between the diversion gate, both in the collection tank with pressure chamber between the retaining plate also has a diversion gate, to prevent the passage of water vapor mist directly from the collection tank and equalizing chamber is discharged, the purification efficiency improves.

4. Due to the water vapor mixing chamber provided with at least a pan of water board, so that water vapor mist air mixing chamber contains sufficient soluble in water, improve the purification efficiency.

5. Because of the water by adding a mist cleaning agents, paint mist undermine adhesion, cohesion so loose paint mist settling on the bottom for easy cleaning.

6. As in the collection tank with access doors for easy maintenance workers.

Captain Spray Booth(Qingdao Hua Yushun Commercial Co., Ltd)

Is a professional leading factory in China, who is specializing in manufacture kinds of paint spray room system. And also offering full garage equipments, such as

Car care equipment.

Car spray&baking room system

Bus spray&baking room system

Furnitue spray&baking room system

Industrial painting&baking room system

High temperature baking room system

Customized spray&bake booth and Offer car spray baking booth accossories

Services We Supply

Customized service

More Than 90% Of Our Spraying Booth Is Customized.

1. We can design the machines according your requirements. At the same time, our engineers will give you our professional suggestions.

2. We can give you free technical support and consultation such as design your factory, make the factory layout drawing and so on.

After-sales service

1. Our fast and professional after service engineer team can go to your factory and install the machine, give you the operating guidance, and train your employees until they can operate the machine well.

2. We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.

3. We provide 2 years warranty.

Captain Advantages

*The same price higher quality, the same quality lower price! ! !

*2 years quality warranty! ! !

*Fast and stable supply capability! ! !

*Personalized design to meet customer various needs! ! !

Competitive Price and High Quality Spraying Booth with Perfect Service Is From Here.