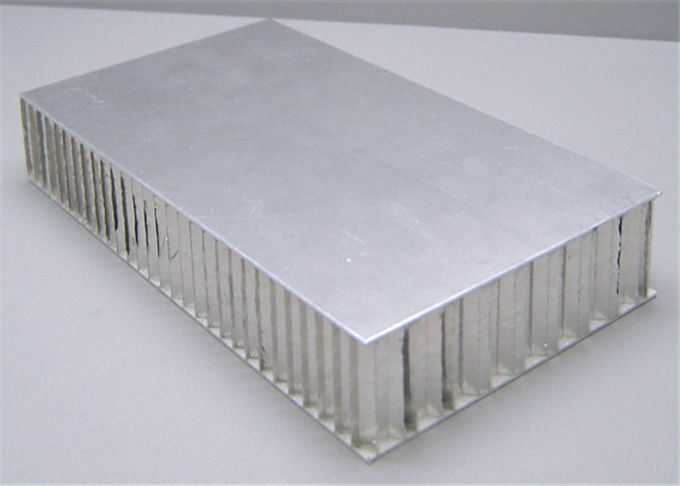

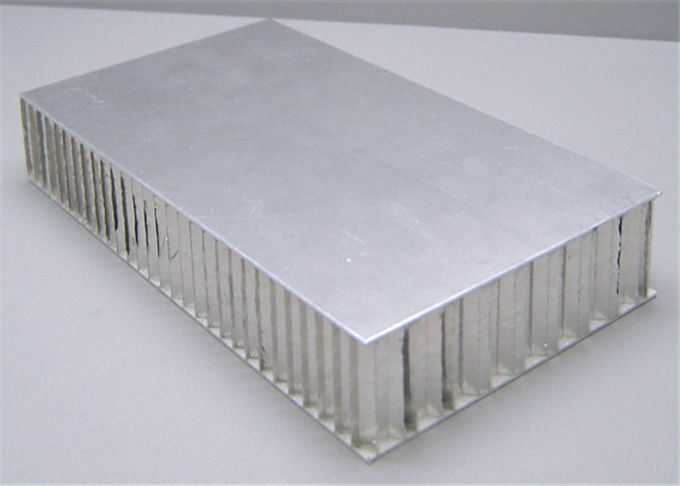

100-200mm ultra-thick Aluminum Honeycomb Sandwich Panel is featured with Lightweigth but High Stiffness and strength, widely used for flooring, facade cladding, ceiling, interior decoration and industrial uses like producing furniture, tables, cabinets, doors, vehicle boards etc.

Available thickness of aluminium skins: 0.5mm~3.0mm

Available Thickness range of panel: 6mm~200mm, specified thickness available.

Size range: 300mm x 300mm ~ 1,500mm x 12,500mm, customized sizes available.

Color range: RAL series colors, marble grains & colors, stone grains & colors, granite grains & colors, wooden grains & colors

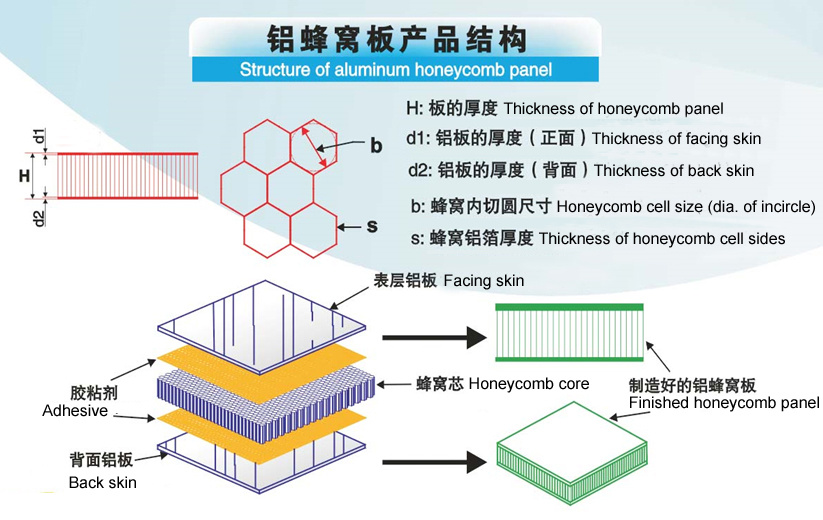

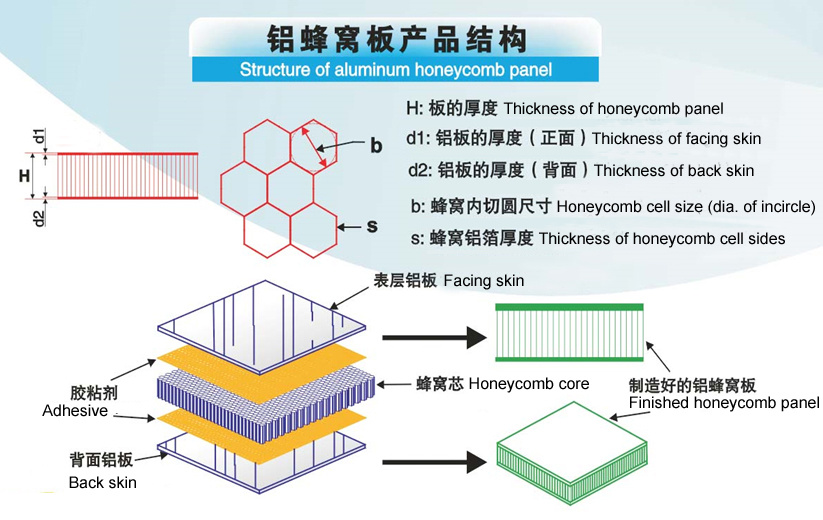

How a Honeycomb Panel is made?

The honeycomb panel is typically made of 5 layers -- decorative skin, adhesive, honeycomb core, adhesive and back skin -- by sandwich lamination.

Materials with high tensile and compression strength are best suited to being skins,such as aluminum, anodized aluminum, galvanized steel, stainless steel, Titanium zinc alloy, copper, fiberglass etc..

Adhesive varies widely by application: high strength, high temperature, low temperature etc.

A variety of honeycomb cores are available as per design requirements for materials and cell sizes to make specified panel thickness (6mm to 200mm).

The illustration of honeycomb panel composition:

Features and Advantages

The honeycomb panel is made with Honeycomb structure core inside, the honeycomb structures that have the geometry of a honeycomb to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells formed between thin vertical walls. The cells are often columnar and hexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

• Low weight. Much llower weight than single metal panel in the same thickness.

• High stiffness and high impact strength.

• Good flatness.

• Easy to fabricate and install

• Recyclable

• Environment-friendly material.

• Sound proofing and thermal insulation.

• Wide variety of optional colors: RAL colors, wood grain colors, marble or granite grain colors, chameleon mixed colors etc.

• Brushed and anodised aluminum finishes are also available.

• Wide range of uses: building decoration, shipbuilding, furnitures, aerospace or automobile.

• Flexible in thickness of honeycomb panels: 6mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 100mm, 200mm etc. available.

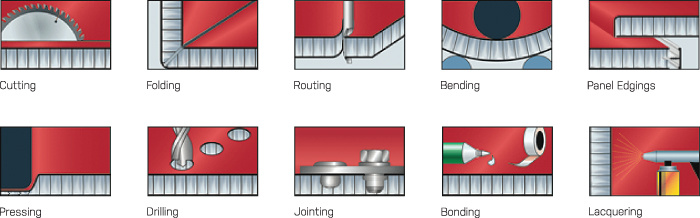

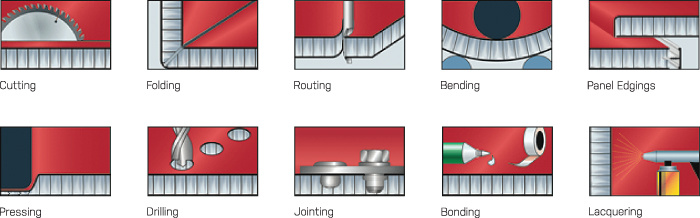

The Aluminium honeycomb panel is very easy to fabricate and install

Applications:

Packing: Palletized wooden box

Available thickness of aluminium skins: 0.5mm~3.0mm

Available Thickness range of panel: 6mm~200mm, specified thickness available.

Size range: 300mm x 300mm ~ 1,500mm x 12,500mm, customized sizes available.

Color range: RAL series colors, marble grains & colors, stone grains & colors, granite grains & colors, wooden grains & colors

How a Honeycomb Panel is made?

The honeycomb panel is typically made of 5 layers -- decorative skin, adhesive, honeycomb core, adhesive and back skin -- by sandwich lamination.

Materials with high tensile and compression strength are best suited to being skins,such as aluminum, anodized aluminum, galvanized steel, stainless steel, Titanium zinc alloy, copper, fiberglass etc..

Adhesive varies widely by application: high strength, high temperature, low temperature etc.

A variety of honeycomb cores are available as per design requirements for materials and cell sizes to make specified panel thickness (6mm to 200mm).

The illustration of honeycomb panel composition:

| Technical data of Aluminum Honeycomb Panel | ||||||||

| No. | Tested Item | Criterion | Specifications | |||||

| Façade Use | Surface Finish | |||||||

| PVDF coating | PE coating | |||||||

| 1 | Coating hardness | GB/T6739 | ≥HB | |||||

| 2 | Coating gloss tolerance | GB/T9754 | ≤10 | |||||

| 3 | Coating flixibility | GB/T17748 | T≤2 | T≤3 | ||||

| 4 | Coating adhesion | GB/T9286 | Grade 0 | |||||

| 5 | Coating abrasion resistance | GB/T17748 | ≥5(L/μm) | -- | ||||

| 6 | Coating muriatic acid resistance | GB/T17748 (for PVDF coating);GB/T22412 (for PE coating) | No change after testing | |||||

| 7 | Coating oil resistance | No change after testing | ||||||

| 8 | Coating alkali resistance | no blistering, swelling, powdering etc. Color deviation △E≤2 | ||||||

| 9 | Coating nitric acid resistance | no blistering, swelling, powdering etc. Color deviation △E≤5 | ||||||

| 10 | Coating solvent resistance | No corroded coating after testing | ||||||

| 11 | Coating dust resistance | GB/T9780 | ≤5% | |||||

| 12 | Coating salt fog resistance | GB/T17748 (for PVDF coating);GB/T22412(for PE coating) | Not less than grade 1, no peeling of coating after testing | |||||

| 13 | Aging test | Color deviation | △E≤4.0 | △E≤2.0 | ||||

| Gloss loss | not less than grade 2 | |||||||

| Aging performance | grade 0 | |||||||

| Appearance | No peeling of adhesion | |||||||

| 14 | Peeling strength by rolling | Average | GB/T1457 | ≥50(N·mm/mm) | ≥40(N·mm/mm) | |||

| Minimum | ≥40 | ≥30 | ||||||

| Peeling strength declining ratia | ≤10% | ≤10% | ||||||

| 15 | Flat push adhesion strength | Average | GB/T1452 | ≥1.0MPa | ≥0.6MPa | |||

| Min. | ≥0.6MPa | ≥0.4MPa | ||||||

| 16 | Flat compressing strength | GB/T1453 | ≥1.0 Mpa | ≥0.6 Mpa | ||||

| 17 | Flat compressing elastic modulus | ≥30MPa | ≥25MPa | |||||

| 18 | Flat shearing strength | GB/T1455 | ≥0.5MPa | ≥0.4MPa | ||||

| 19 | Flat shearing elastic modulus | ≥4.0MPa | ≥3.0MPa | |||||

| 20 | Bending hardness | GB/T1456 | ≥1.0×108 | N·mm2 | ||||

| 21 | Shearing hardness | ≥2.0×104 | N | |||||

| 22 | Flexible impact resistance | GB/T21086-2007 | No deformation or damage after testing | |||||

| Crash resistance | ||||||||

| 23 | Boiled water resistance | Appearance | GB/T17748(tested sample 80×350mm) | No abnormity after testing | ||||

| Coating adhesion | grade 0 | |||||||

| Average peeling strength by rolling | ≥40(N·mm/mm) | ≥30(N·mm/mm) | ||||||

| 24 | Temperature resistance | Appearance | GB/T17748(tested sample80×350mm) | No abnormity after testing | ||||

| Adhesion | Grade 0 | |||||||

| Average peeling strength by rolling | ≥40(N·mm/mm) | ≥30(N·mm/mm) | ||||||

Features and Advantages

The honeycomb panel is made with Honeycomb structure core inside, the honeycomb structures that have the geometry of a honeycomb to allow the minimization of the amount of used material to reach minimal weight and minimal material cost. The geometry of honeycomb structures can vary widely but the common feature of all such structures is an array of hollow cells formed between thin vertical walls. The cells are often columnar and hexagonal in shape. A honeycomb shaped structure provides a material with minimal density and relative high out-of-plane compression properties and out-of-plane shear properties.

• Low weight. Much llower weight than single metal panel in the same thickness.

• High stiffness and high impact strength.

• Good flatness.

• Easy to fabricate and install

• Recyclable

• Environment-friendly material.

• Sound proofing and thermal insulation.

• Wide variety of optional colors: RAL colors, wood grain colors, marble or granite grain colors, chameleon mixed colors etc.

• Brushed and anodised aluminum finishes are also available.

• Wide range of uses: building decoration, shipbuilding, furnitures, aerospace or automobile.

• Flexible in thickness of honeycomb panels: 6mm, 8mm, 10mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 50mm, 60mm, 100mm, 200mm etc. available.

| Mechanical Properties of Aluminum Honeycomb Panels | |||||||||||||||

| Thickness of Panel | 10mm | 15mm | 20mm | 25mm | 30mm | 40mm | 50mm | ||||||||

| Thickness of Alu. Skins | 1+1(mm) | 0.8+0.8(mm) | 1+1(mm) | 0.8+0.8(mm) | 1+1(mm) | 0.8+0.8(mm) | 1+1(mm) | 0.8+0.8(mm) | 1+1(mm) | 0.8+0.8(mm) | 1+1(mm) | 0.8+0.8(mm) | 1+1(mm) | 0.8+0.8(mm) | |

| Weigth/(kg/m2) | 6.6 | 5.6 | 7.0 | 5.8 | 7.3 | 6.1 | 7.5 | 6.3 | 7.8 | 6.6 | 8.3 | 7.1 | 8.8 | 7.6 | |

| Horizontal Tensile Strength/MPa | ≥0.8 | ||||||||||||||

| Horizontal Compressing Strength(Mpa) | ≥0.9 | ||||||||||||||

| Horizontal Compressing Elastic Modulus(Mpa) | ≥30 | ||||||||||||||

| Impact performance | No obvious deformation or damage | ||||||||||||||

| Rigidity Coefficient (Nmm2/mm) | 0.27×107 | 0.23×107 | 0.67×107 | 0.55×107 | 1.2×107 | 1.0×107 | 2.0×107 | 1.6×107 | 2.9×107 | 2.3×107 | 5.2×107 | 4.2×107 | 8.2×107 | 6.6×107 | |

| Anti-impact section factor (mm3/mm) | 8.1 | 6.7 | 13 | 10.7 | 18 | 14.7 | 23 | 18.7 | 28 | 22.7 | 38 | 30.7 | 48 | 38.7 | |

| Hot water resistance(Boiled in 98 ºCwater for 2 hours) | No peeling between honeycomb core and Aluminum sheets | ||||||||||||||

| Temperature difference resistance( Test cycle: constant 40 ºC for 2 hours, constant 80 ºCfor 2hours,totally 50 cycles) | |||||||||||||||

The Aluminium honeycomb panel is very easy to fabricate and install

Applications:

- Architectural Building Cladding and decoration

- Architectural Rainscreen Facades

- Lightweight interior architectural panels

- Wall panels, ceiling panels, roofing panels and partitions.

- Tables, cabinets and furnitures.

- Aerospace, Marine & Transport Flooring, Walls & Partitions

- Silk Screen Printing Tables or Billboards

- CNC Vacuum Bases

- Lightweight Floors, Walls, Ceilings, etc

- Special Purpose Panel Design

Packing: Palletized wooden box